Certainly! Here are some frequently asked questions (FAQ) regarding the manufacturing and quality work of the KTA19 engine at the MEP Power factory:

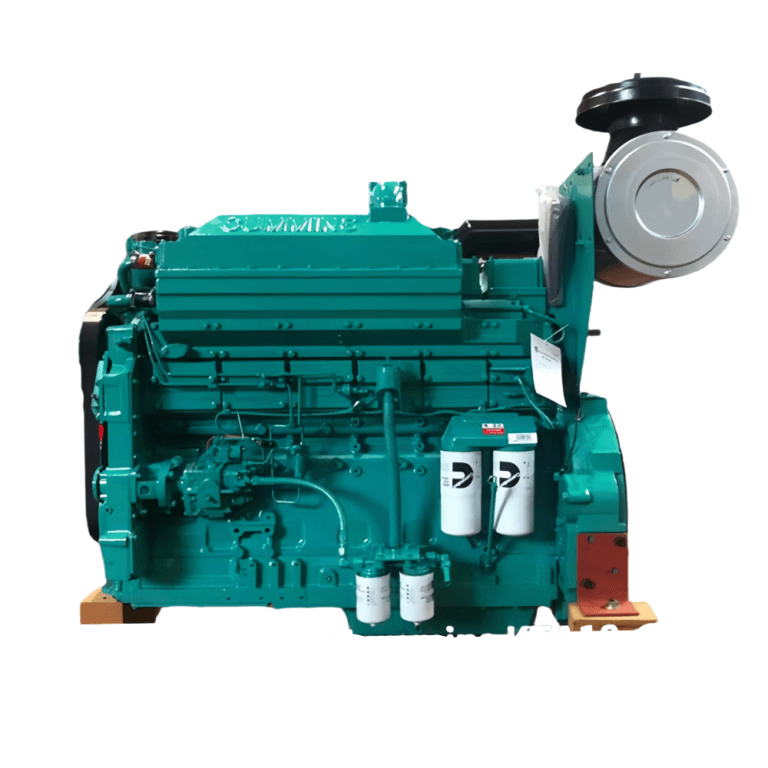

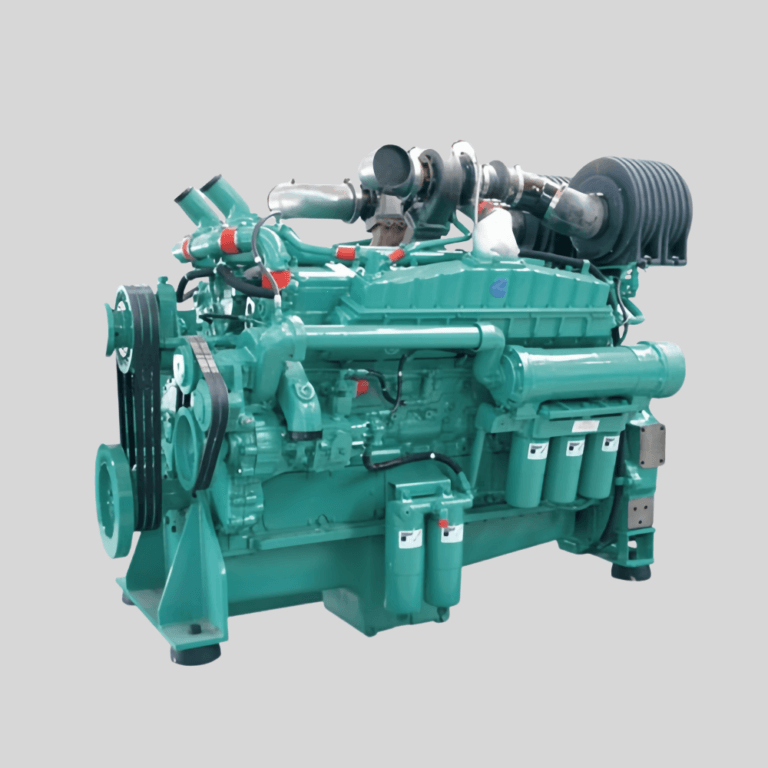

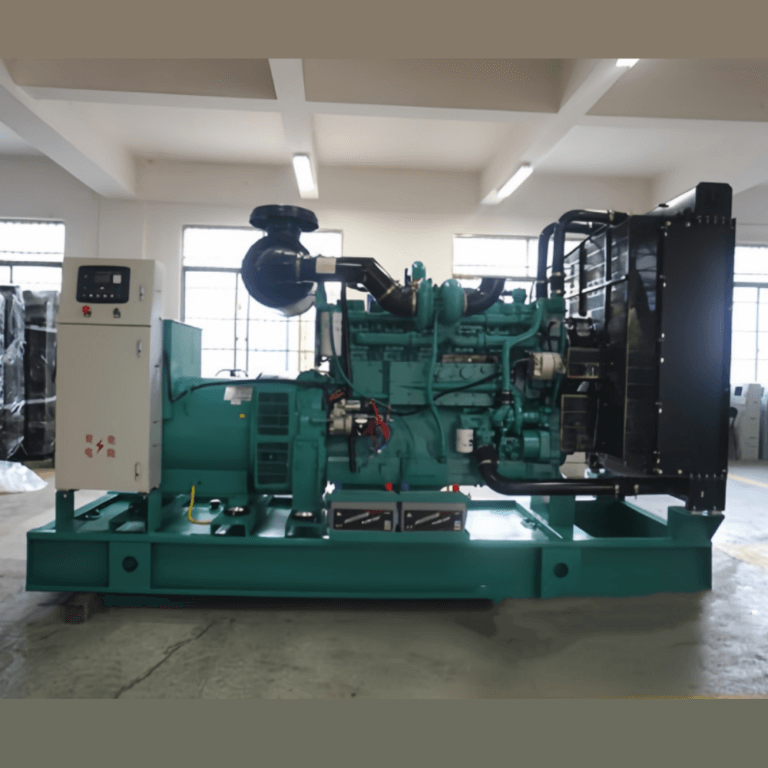

Q: What is the KTA19 engine?

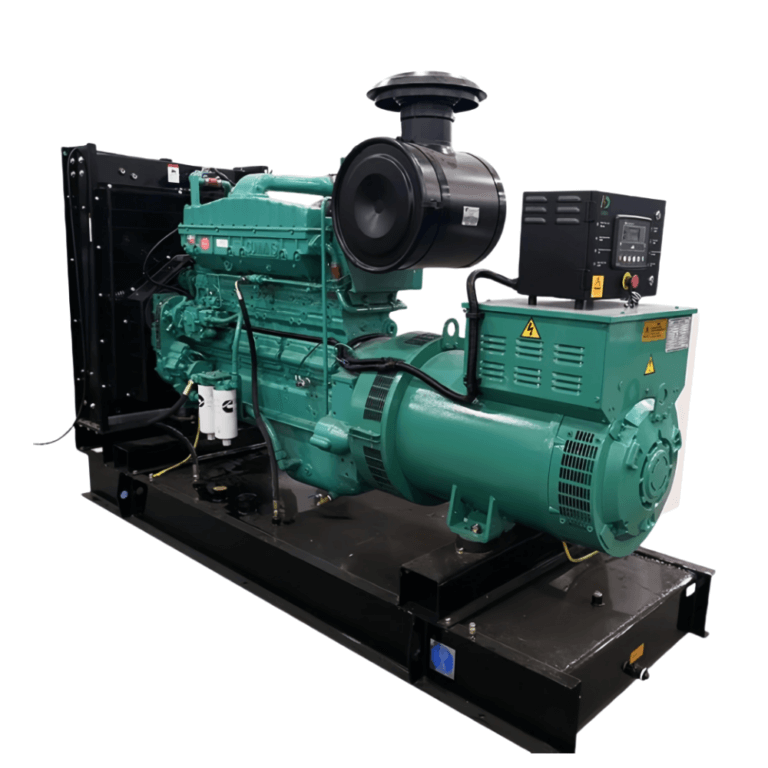

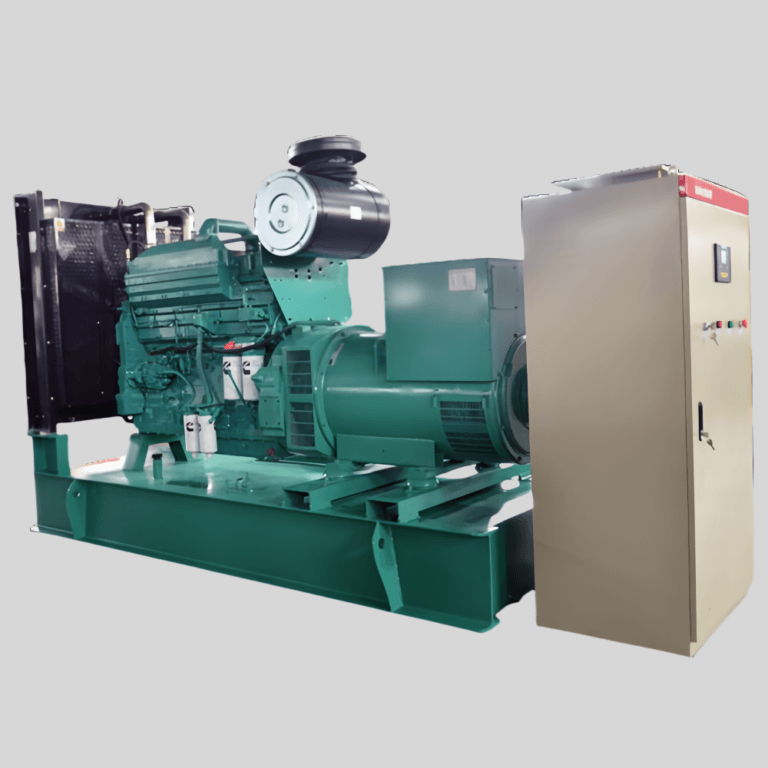

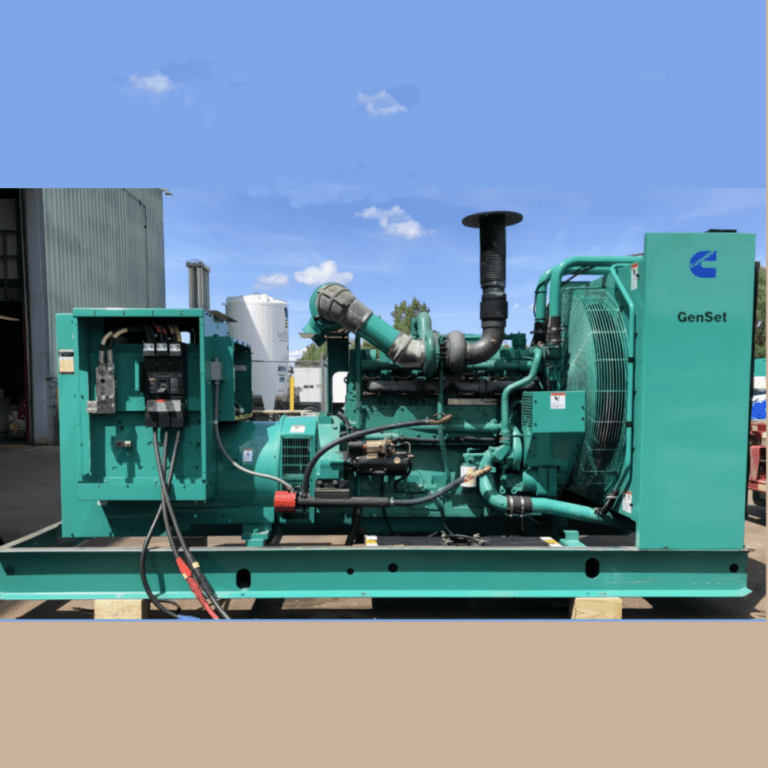

A: The KTA19 is a high-performance, diesel-powered engine known for its reliability and efficiency. It is used in various applications, including power generation, Industrial engines, and marine propulsion.

Q: What ensures the quality of the KTA19 engine at MEP Power factory?

A: The MEP Power factory employs stringent quality control protocols, state-of-the-art manufacturing technologies, and consistent testing mechanisms to ensure the highest quality of KTA19 engines. Compliance with international standards is also maintained.

Q: What kind of testing is performed on the KTA19 engine during manufacturing?

A: Multiple stages of testing are performed including material inspection, dimensional verification, performance tests, and endurance testing to guarantee that each engine meets the required specifications.

Q: How does MEP Power factory handle defective parts?

A: Any defective part spotted during the manufacturing or quality control processes is immediately isolated, and a thorough root cause analysis is performed. Corrective actions are implemented to prevent recurrence.

Q: What certifications does MEP Power factory hold for manufacturing the KTA19 engine?

A: MEP Power factory holds ISO 9001 certification for quality management systems and ensures that all products meet or exceed industry regulations and standards.

Q: Can the KTA19 engine be customized according to specific requirements?

A: Yes, MEP Power factory offers customization options for the KTA19 engine to meet specific customer requirements. Customization can include adjustments in power output, ancillary equipment, and installation configurations.

Q: What are the maintenance guidelines for KTA19 engines?

A: Maintenance guidelines generally include regular oil changes, periodic filter replacements, fuel system checks, and cooling system inspections. Detailed maintenance instructions are provided in the engine manual.

Q: How does MEP Power support after-sales service for KTA19 engines?

A: MEP Power offers comprehensive after-sales support, including warranty services, maintenance contracts, and readily available spare parts. A dedicated customer service team is also available to resolve any issues promptly.

Q: How can I place an order for the KTA19 engine from MEP Power factory?

A: Orders can be placed directly through MEP Power’s official website, contacting their sales department, or through authorized distributors.