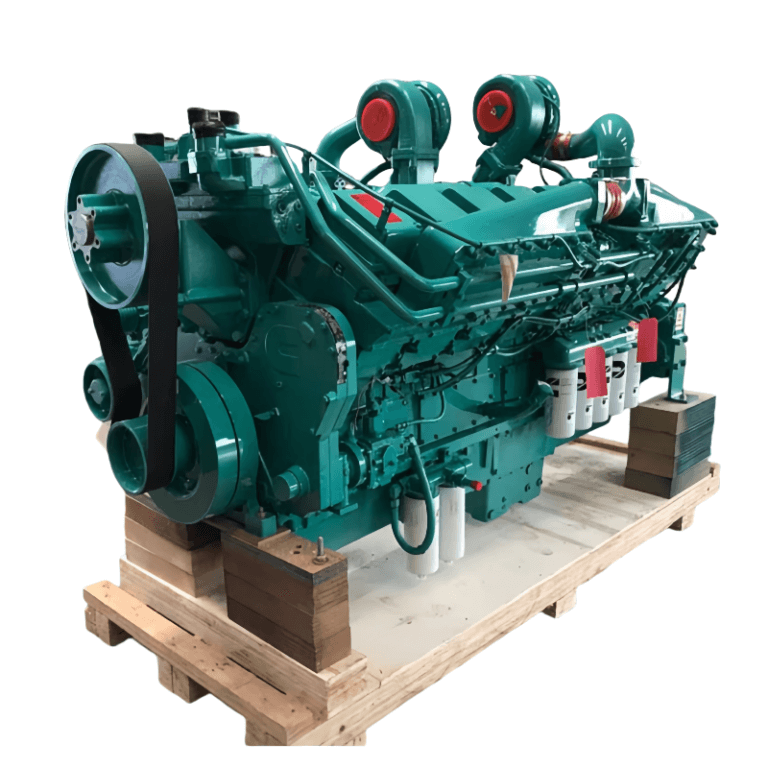

Sourcing a KTA50 engine from MEP Power factory involves several key steps for a successful acquisition. Here are concise tips to facilitate the process:

1. Research and Identification:

– Determine the specific variant of the KTA50 engine model you need. There might be differences in power ratings and configurations based on your requirements.

2. Contact MEP Power:

– Visit MEP Power factory’s official website and locate their contact information.

– Use the provided email or contact form for initial inquiries. Phone calls can also be effective for direct communication.

3. Request for Proposal (RFP):

– Prepare a detailed RFP outlining specifications, quantity, delivery schedule, and any special requirements.

– Send this RFP to the sales or business development department of MEP Power.

4. Verify Credibility:

– Ensure MEP Power is an authorized manufacturer or distributor of KTA50 engines, by checking certifications and reviews.

– You may want to check for any affiliations with reputable industry associations or certifications.

5. Request Documentation:

– Ask for documentation such as product datasheets, quality certifications, and compliance with industry standards.

6. Negotiate Terms:

– Discuss terms of pricing, warranty, after-sales service, and parts support.

– Compare with other potential suppliers to ensure competitive pricing and terms.

7. Payment and Incoterms:

– Agree on payment terms (advance, letter of credit, etc.) and Incoterms (FOB, CIF, etc.) for the shipment.

8. Inspect and Confirm:

– Before finalizing, you might want to inspect the factory or request a third-party inspection to ensure the engine meets your standards.

9. Legal and Logistical Considerations:

– Ensure all legal and shipping documentation is in place.

– Arrange for logistics, taking into consideration the import regulations of your country.

10. After-Sales Support:

– Confirm availability of technical support and parts post-purchase for maintenance and troubleshooting.

By following these steps, you can streamline the process of sourcing a KTA50 engine from MEP Power factory effectively.