What is the availability of KTA19 engines from MEP Power factory?

MEP Power maintains a robust inventory of KTA19 engines, ensuring immediate availability for most orders. Please contact our sales team for current stock levels.

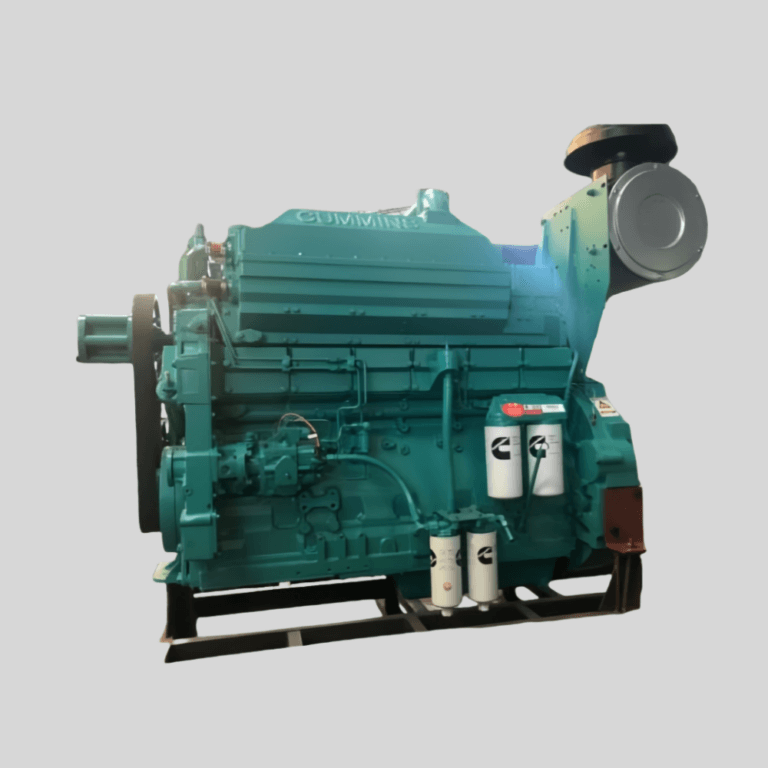

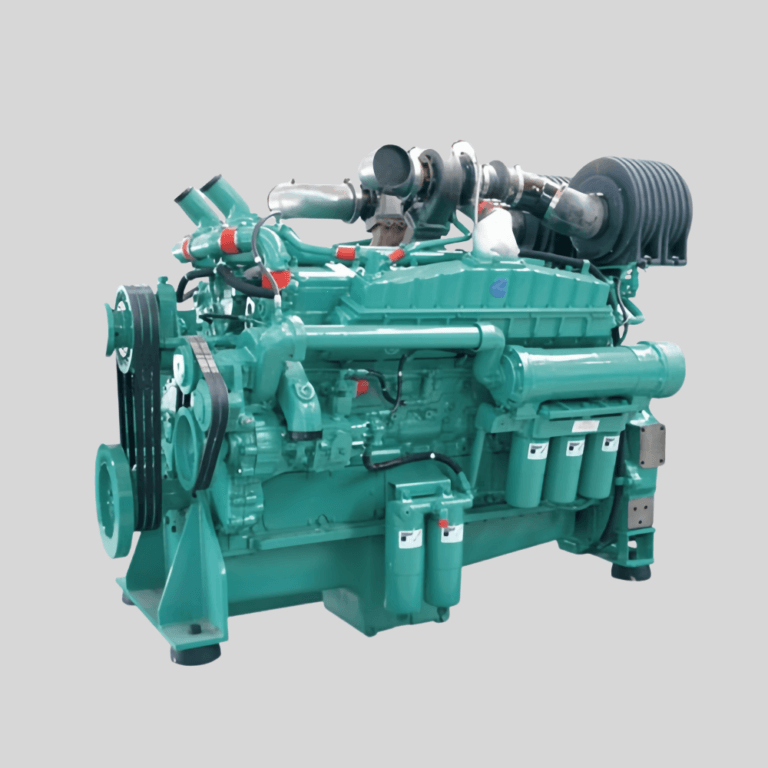

What are the specifications of the KTA19 engines available?

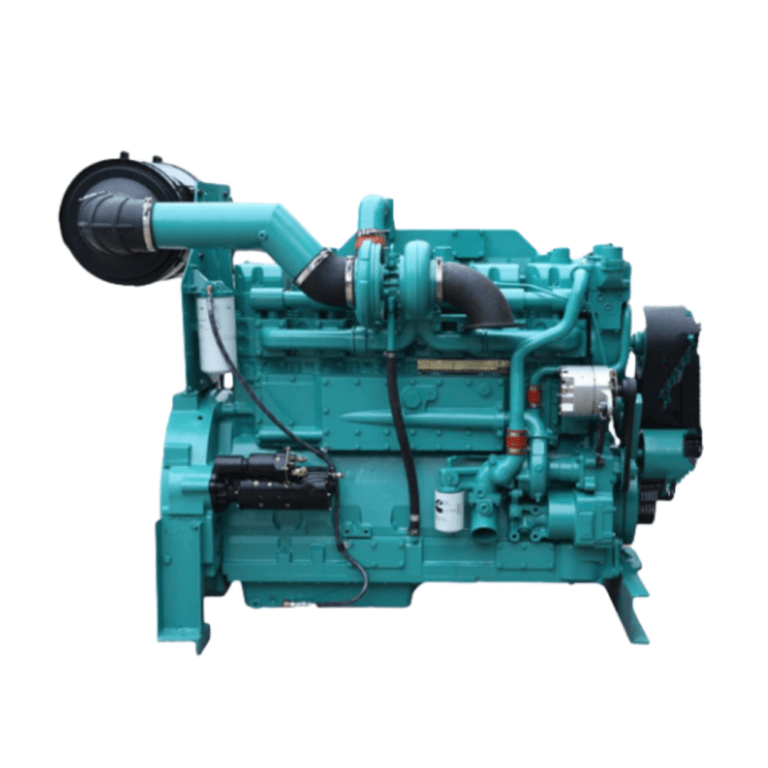

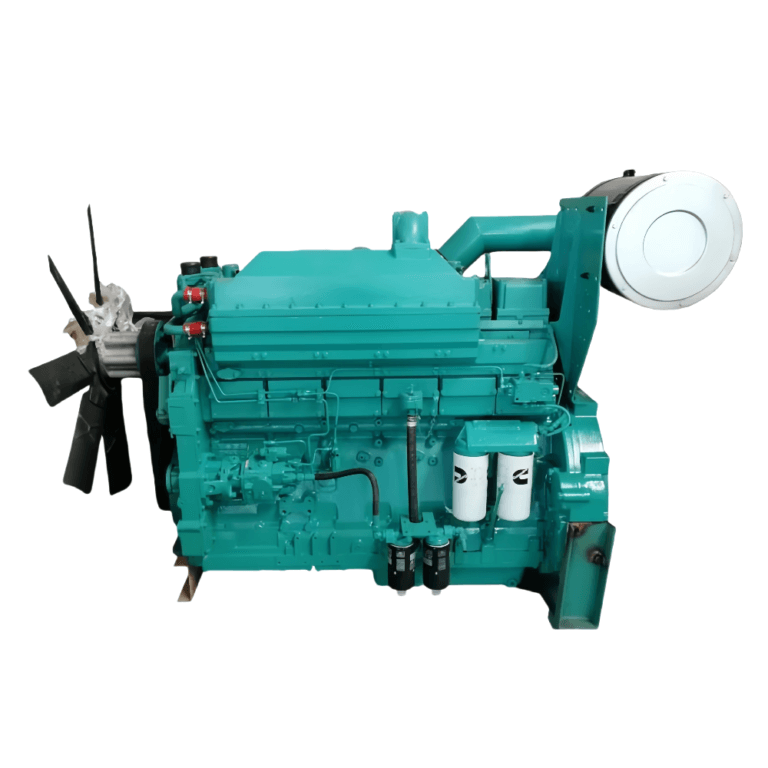

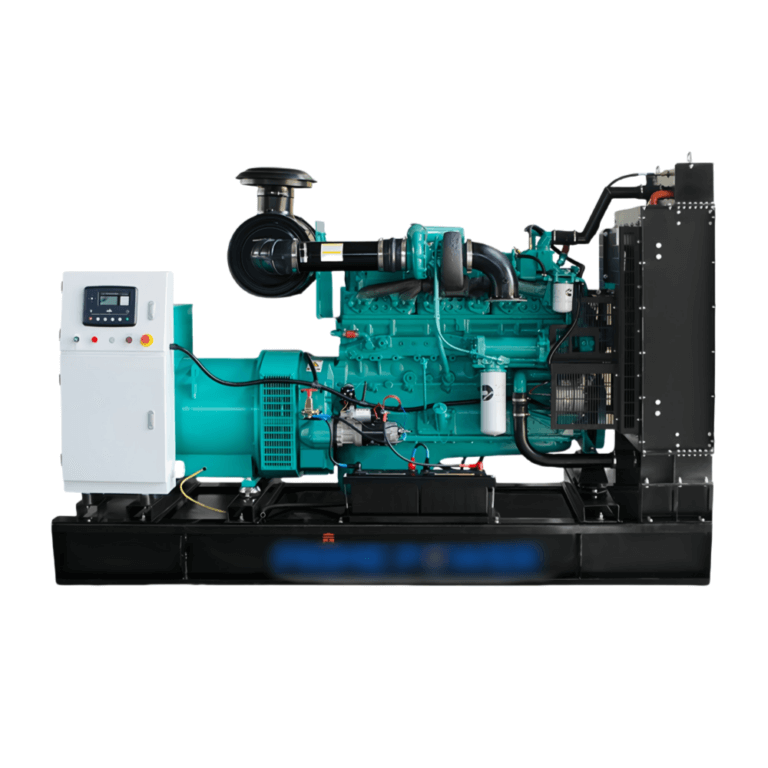

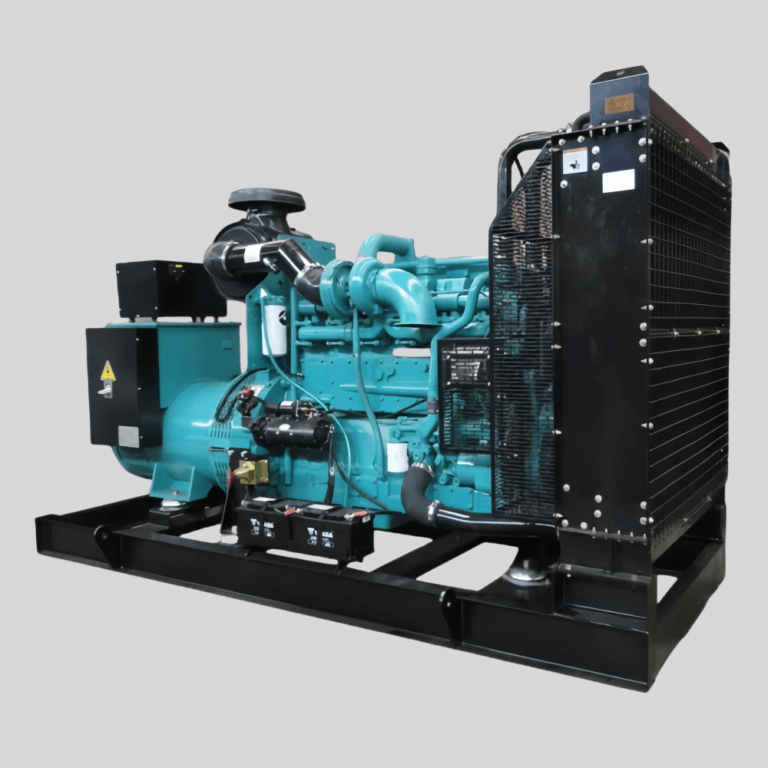

The KTA19 engines from MEP Power adhere to Cummins’ specifications, featuring a 19L displacement, 6-cylinder inline configuration, and a power range from 450 to 700 HP, depending on the application.

Do you offer customization options for KTA19 engines?

Yes, MEP Power can customize KTA19 engines to meet specific requirements, including alternator options, control panel settings, and other modifications to suit your application.

What kind of warranty and after-sales support do you provide?

We offer a standard manufacturer’s warranty on all KTA19 engines and comprehensive after-sales support, including maintenance services and spare parts availability.

Are your KTA19 engines compliant with emission regulations?

Yes, our KTA19 engines comply with international emission standards, ensuring they meet the stringent environmental regulations of various countries.

What industries typically use KTA19 engines?

KTA19 engines are versatile and commonly used in industries such as construction, mining, marine, and power generation for their reliability and performance.

How can I place an order for a KTA19 engine?

You can place an order by contacting our sales department via phone, email, or through our website’s inquiry form. Our team will guide you through the purchasing process.

What is the lead time for delivery after placing an order?

Delivery lead times vary based on stock availability and customization requirements. Standard orders typically ship within 2-4 weeks.

Do you provide installation services for KTA19 engines?

Yes, MEP Power offers installation services through our network of certified technicians to ensure proper setup and operation of your KTA19 engine.

Is there a minimum order quantity for KTA19 engines?

No, there is no minimum order quantity. You can order a single unit or multiple units based on your needs.