FAQs for Sourcing QST30 from MEP Power Factory

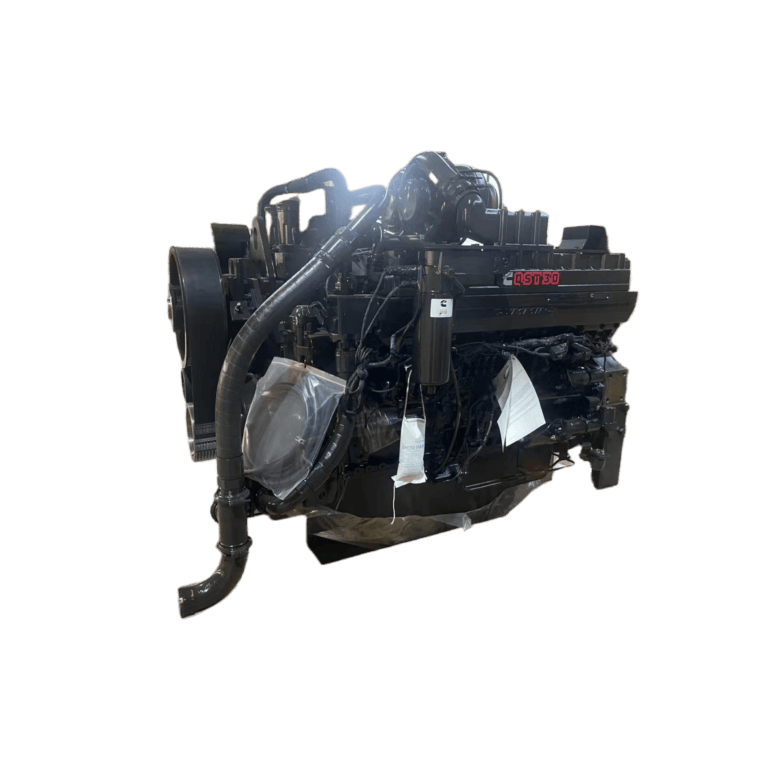

Q: What is QST30?

A: The QST30 is a robust, high-performance diesel engine commonly used in industrial and power generation applications. It is known for its reliability, efficiency, and durability.

Q: What makes QST30 engines suitable for power generation?

A: The QST30 engines are designed for continuous duty, providing consistent power output. They feature advanced fuel injection systems, excellent thermodynamic efficiency, and robust construction, making them ideal for both prime and standby power generation.

Q: How can I source QST30 engines from MEP Power?

A: To source QST30 engines from MEP Power, you can contact their sales department directly via their website or customer service hotline. Inquire about current inventory, pricing, and any bulk purchase discounts.

Q: Are there any certifications or standards that QST30 complies with?

A: Yes, QST30 engines comply with various international standards, including ISO 9001, and may meet specific emission standards such as EPA Tier and EU Stage certifications, depending on the configuration.

Q: What warranty does MEP Power provide for QST30 engines?

A: MEP Power typically offers a standard warranty period, which usually covers major engine components and manufacturing defects. The specifics can vary, so it’s best to confirm the details during the purchasing process.

Q: What kind of maintenance is required for QST30 engines?

A: Routine maintenance for QST30 engines includes regular oil and filter changes, coolant checks, and inspections of fuel and air systems. MEP Power often provides a detailed maintenance schedule with each unit.

Q: Can I get technical support for QST30 engines?

A: Yes, MEP Power offers comprehensive technical support, including troubleshooting assistance, parts replacement, and field service visits. You can access support through their customer service portal.

Q: Are spare parts for QST30 readily available?

A: Spare parts for QST30 engines are generally readily available through MEP Power’s distribution network. Ensure to check for parts availability when placing your order to avoid any delays.

Q: Can I customize the QST30 engine to fit specific needs?