Sure! Below are some of the Frequently Asked Questions (FAQ) along with their answers pertaining to the manufacturing of “MTA11 Quality Work” at MEP Power Factory.

1. What is MTA11 Quality Work?

MTA11 Quality Work refers to a stringent set of manufacturing standards and practices employed by MEP Power Factory to ensure that all products meet high-quality benchmarks, reflecting reliability, efficiency, and durability.

2. How does MEP Power Factory ensure the quality of its products?

MEP Power Factory ensures quality through robust quality control systems, regular inspections, comprehensive testing procedures, and adherence to international standards. Every stage of production is meticulously monitored and documented.

3. What certifications does MEP Power Factory hold?

MEP Power Factory holds several certifications such as ISO 9001 for Quality Management Systems, ISO 14001 for Environmental Management, and OHSAS 18001 for Occupational Health and Safety. These certifications demonstrate our commitment to quality and sustainability.

4. Can MEP Power Factory customize products based on client requirements?

Yes, MEP Power Factory offers customization services to meet specific client needs. We work closely with our clients to understand their requirements and deliver tailor-made solutions.

5. What are the lead times for manufacturing at MEP Power Factory?

Lead times can vary depending on the complexity and size of the order. Typically, it ranges from a few weeks to several months. Clients are encouraged to contact our sales team for a more precise timeline.

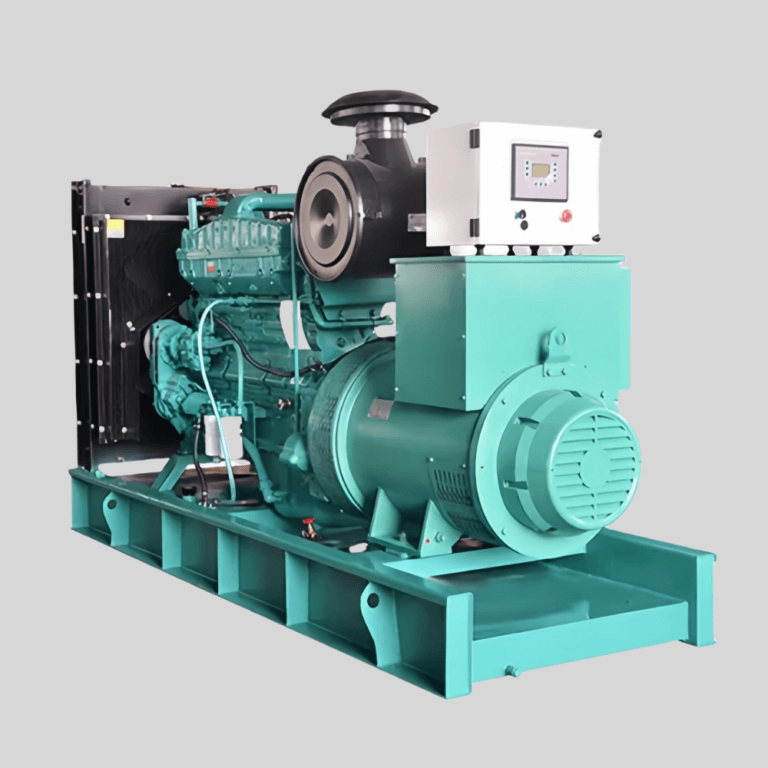

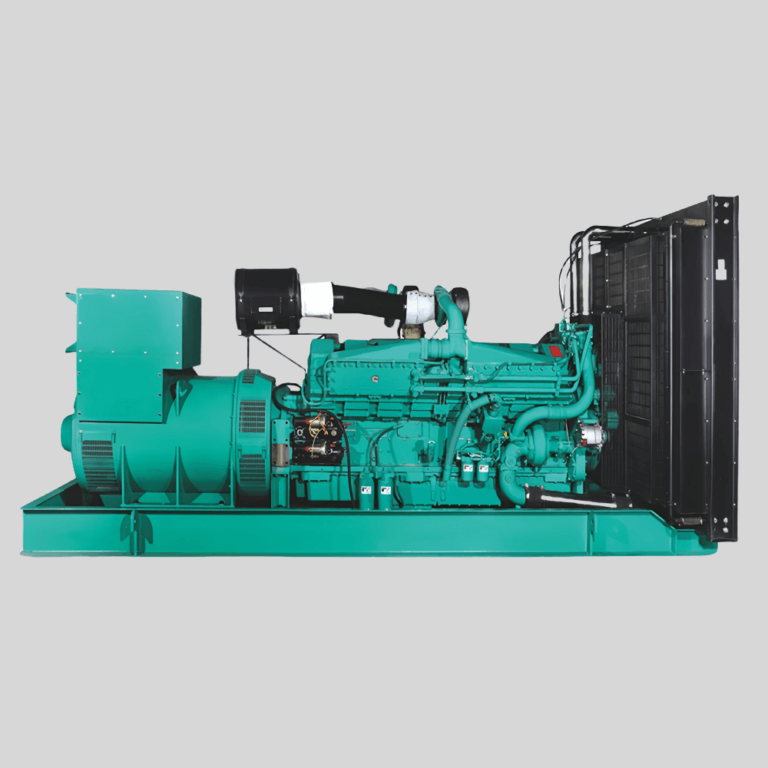

6. What types of products does MEP Power Factory manufacture under MTA11 Quality Work?

MEP Power Factory manufactures a wide range of products including transformers, switchgear, power converters, and other electrical equipment, all adhering to MTA11 Quality Work standards.

7. How are the employees trained to meet MTA11 standards?

Employees at MEP Power Factory undergo rigorous training programs which include both theoretical education and practical hands-on experience. Regular workshops and certifications ensure that our workforce stays updated with the latest industry practices and standards.

8. Are there after-sales services available?

Yes, MEP Power Factory provides comprehensive after-sales services including maintenance, troubleshooting, and technical support to ensure the long-term performance and reliability of our products.

9. How does MEP Power Factory handle client feedback and complaints?

Client feedback and complaints are handled with utmost priority. We have a dedicated customer service team that ensures all issues are addressed promptly and effectively, fostering continuous improvement in our processes.