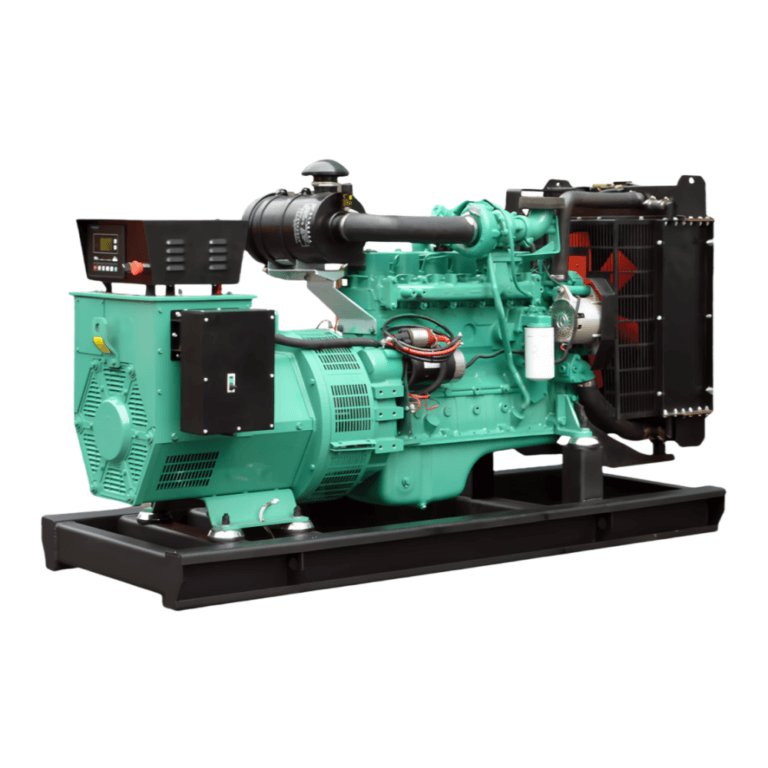

Sourcing the QSZ13 engine from MEP Power factory requires strategic planning and clear communication. Here are some tips to help streamline the process:

1. Identify Specifications:

– Understand the specific requirements for the QSZ13 engine, including power output, configuration, and any unique customization needs.

2. Research Suppliers:

– Begin by researching MEP Power’s official website and catalog to understand their product offerings.

– Look for authorized distributors or dealers who carry MEP Power products.

3. Direct Contact:

– Reach out directly to MEP Power, either through their website contact form, email, or phone. Establishing direct communication can provide clarity and prevent any misunderstandings.

4. Verify Supplier Credentials:

– Verify the credibility of potential suppliers by checking business reviews, testimonials, and certification.

– Use industry networks and trade associations to find reputable sources.

5. Request Information:

– Ask for product datasheets, compliance certifications, and any customer references to gauge reliability.

– Request detailed quotations, including lead times, pricing, and shipping options.

6. Negotiate Terms:

– Negotiate terms of payment, warranties, and after-sales support. Ensure that the agreement covers potential issues such as delivery delays or defects.

7. Visit the Factory:

– If feasible, arrange a visit to MEP Power’s factory to inspect the manufacturing process and quality control measures.

8. Utilize Supply Chain Contacts:

– Leverage existing contacts in the industry for recommendations and insights regarding MEP Power’s reputation and product quality.

9. Check Legal Compliance:

– Ensure that all transactions comply with local and international trade laws, including import/export regulations.

10. Monitor Order Progress:

– Maintain ongoing communication with the supplier to monitor the status of the order and address any issues promptly.

By following these steps, you can more efficiently source the QSZ13 engine from MEP Power factory with confidence.