Sure, below are some FAQs and their corresponding answers for manufacturing a “750 kW Generator quality work from MEP Power factory”:

Q: What is the typical lead time for manufacturing a 750 kW generator?

A: The typical lead time for manufacturing a 750 kW generator can range from 8 to 16 weeks, depending on customization requirements and current production schedules.

Q: What quality standards does MEP Power factory adhere to?

A: MEP Power factory adheres to international quality standards, such as ISO 9001, ISO 14001, and OHSAS 18001 certifications to ensure high-quality manufacturing processes and products.

Q: Are the generators tested before delivery?

A: Yes, each generator undergoes rigorous testing, including load testing, performance testing, and safety inspections, to ensure optimal performance and reliability before being shipped to the customer.

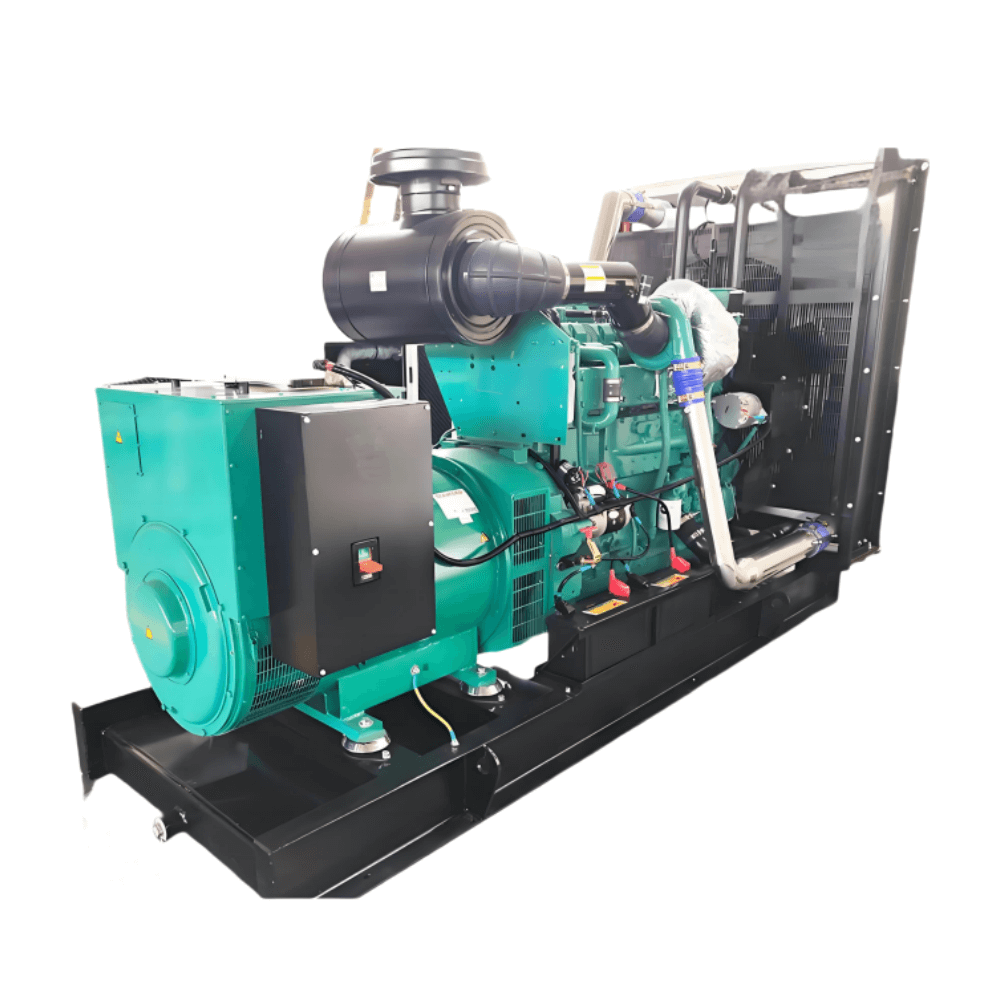

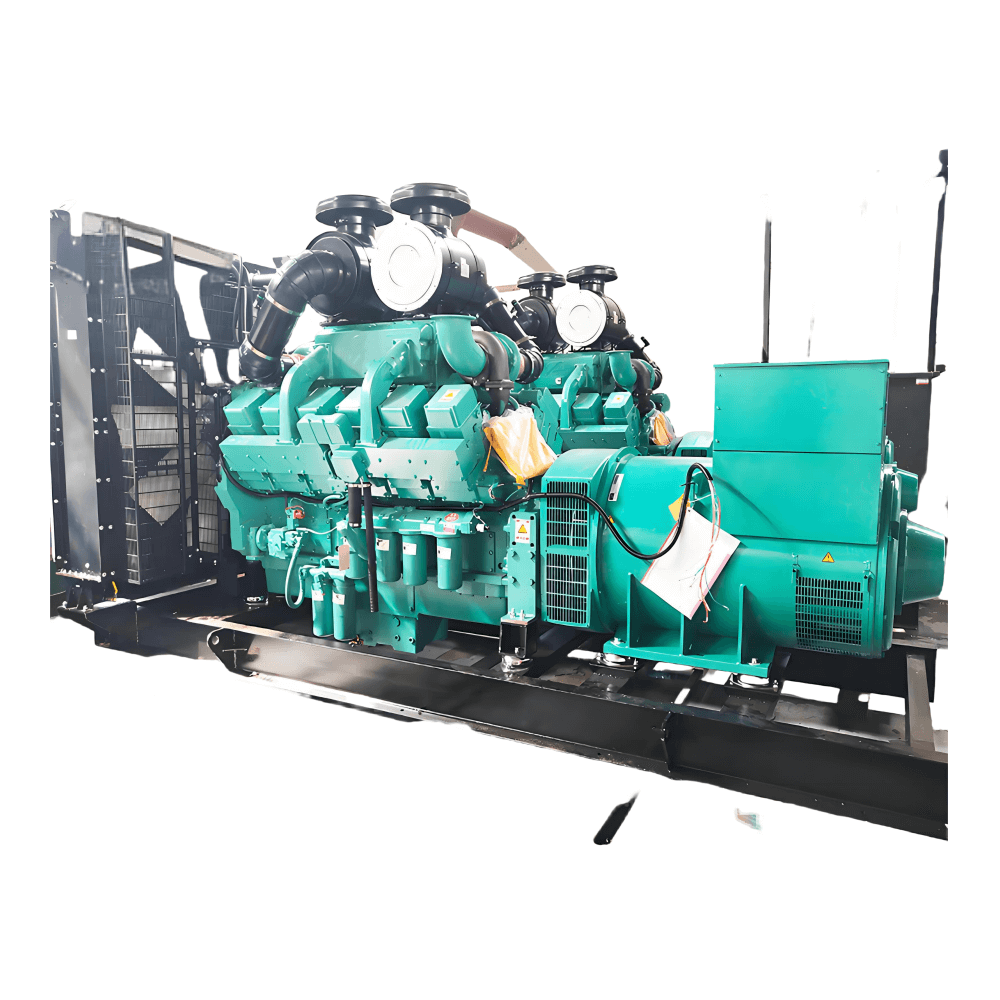

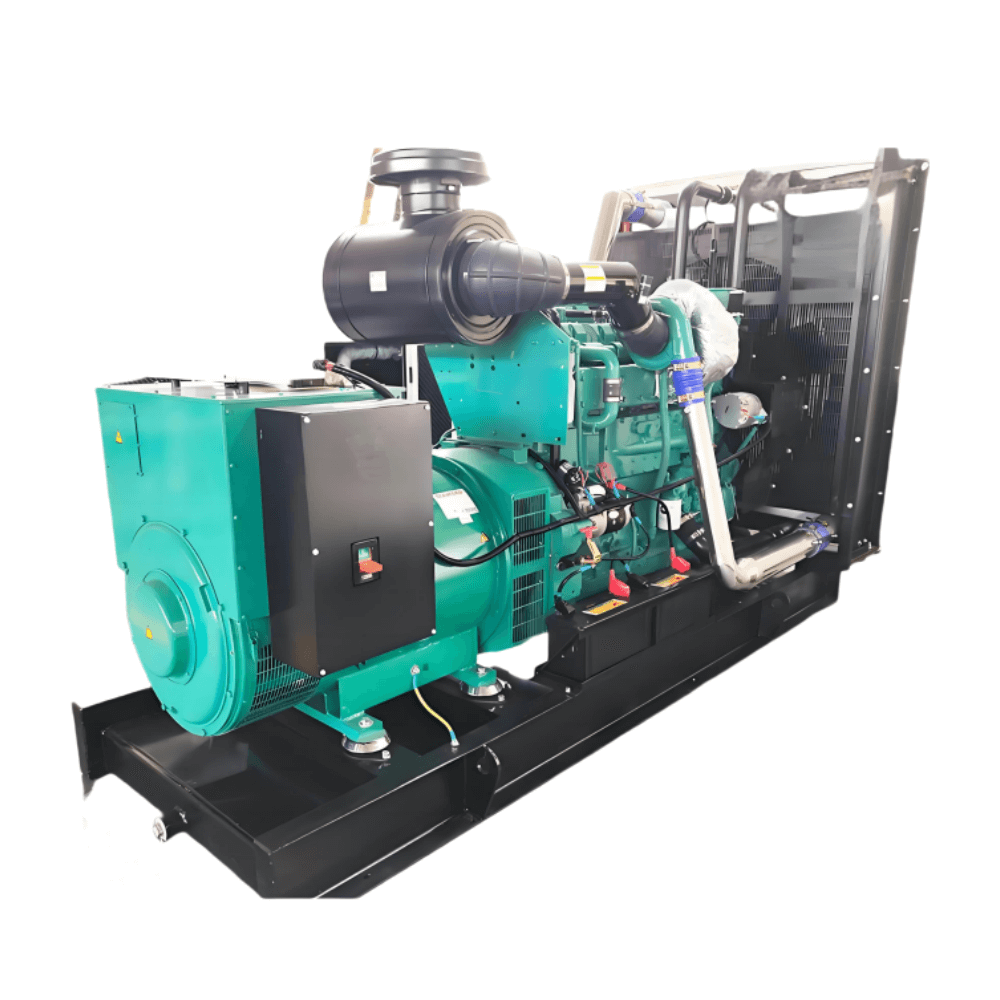

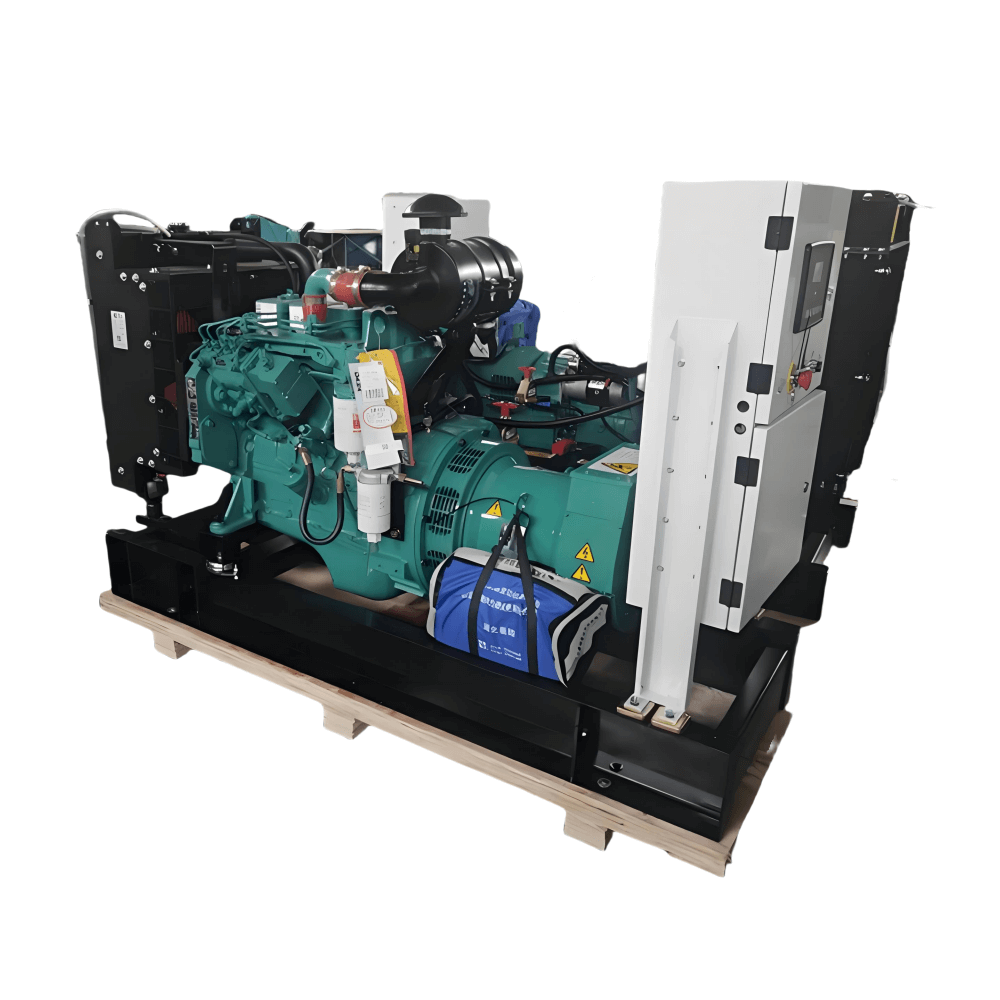

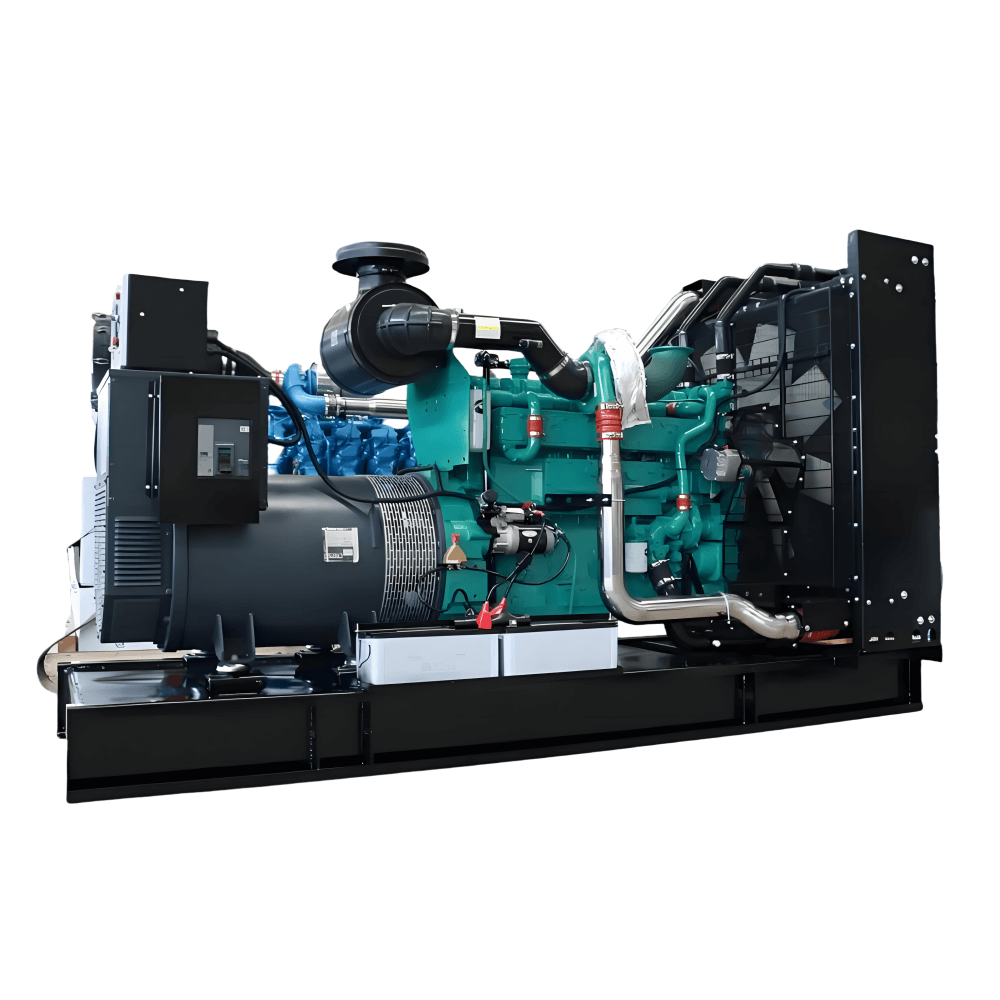

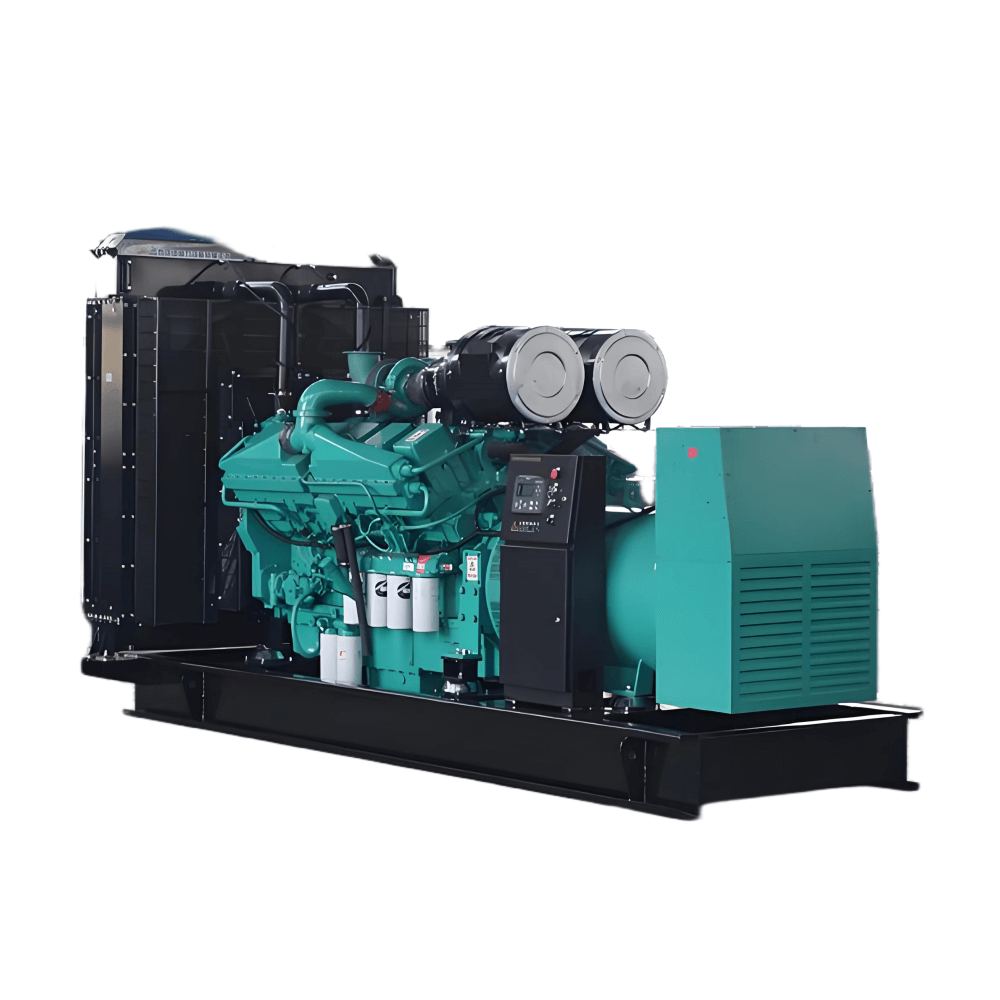

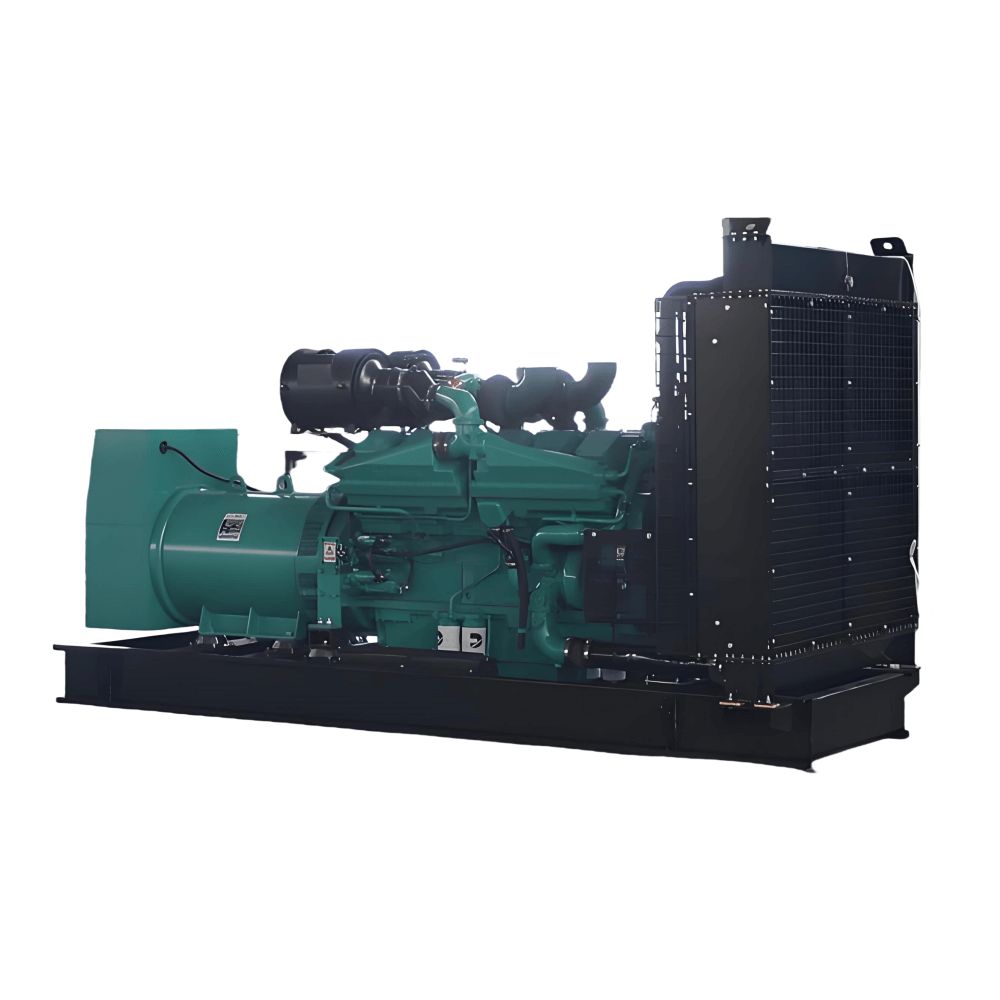

Q: What are the key features of a 750 kW generator from MEP Power?

A: Key features include robust construction, high fuel efficiency, advanced control systems, low noise levels, and comprehensive safety mechanisms to ensure reliable, uninterrupted power supply.

Q: How does MEP Power factory ensure the durability of the generator?

A: MEP Power ensures durability by using high-quality materials, implementing advanced engineering techniques, and conducting extensive durability tests under various environmental conditions.

Q: Is there a warranty provided for the 750 kW generators?

A: Yes, MEP Power provides a comprehensive warranty, which typically covers one to two years, depending on the specific terms and conditions of the purchase agreement.

Q: Can the 750 kW generator be customized to meet specific requirements?

A: Absolutely, MEP Power offers customization options for the 750 kW generator to meet specific requirements related to voltage, frequency, cooling systems, and other operational needs.

Q: What kind of maintenance support does MEP Power offer?

A: MEP Power provides maintenance support, including preventive maintenance programs, spare parts supply, and technical assistance to ensure the long-term performance of the generator.

Q: What are the fuel options for the 750 kW generator?

A: The 750 kW generator can be configured to run on various fuel types, including diesel, natural gas, and dual-fuel options, based on the customer’s preference and application needs.

Q: How can I get a quote for a 750 kW generator?