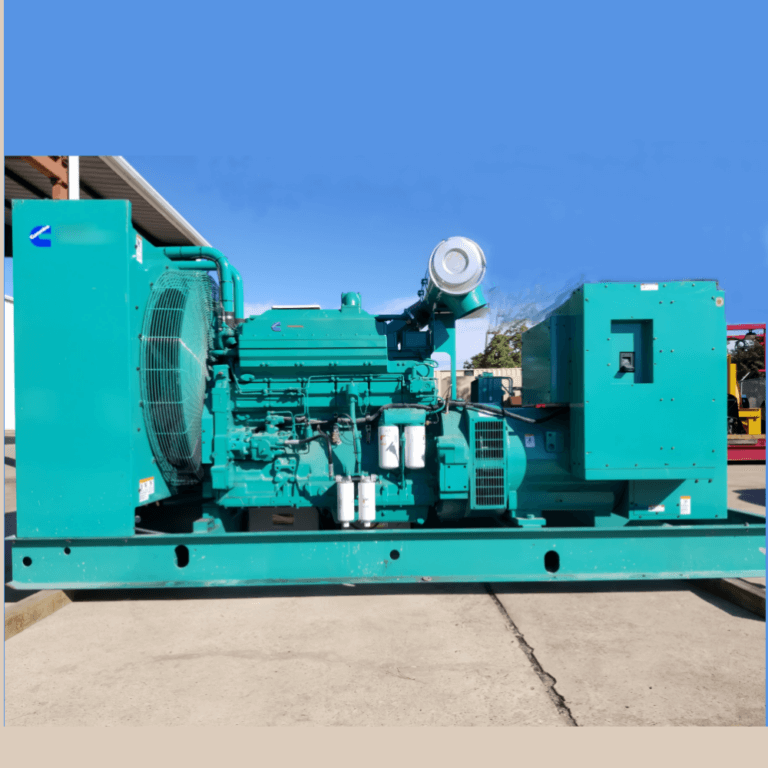

Sure! Here’s a concise FAQ for manufacturing the KTA19 Cummins engine at the MEP Power factory:

Q: What quality standards does MEP Power follow for manufacturing the KTA19 Cummins engine?

A: MEP Power adheres to ISO 9001 quality management standards ensuring high reliability and performance for all their products, including the KTA19 Cummins engine.

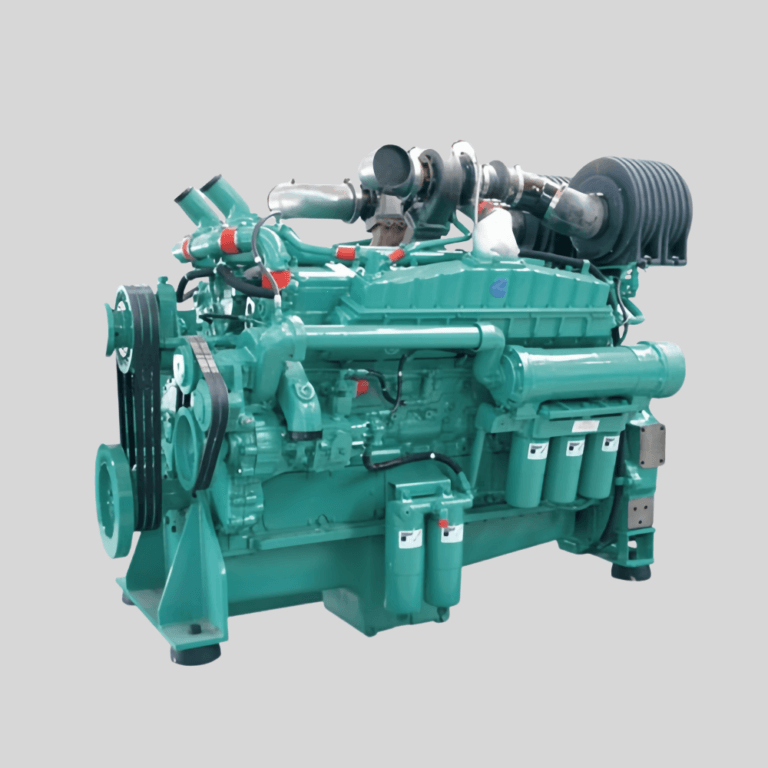

Q: What materials are used in the manufacturing of the KTA19 Cummins engine?

A: The KTA19 Cummins engine is made using high-grade alloy steel for the engine block, cast iron for critical components, and other durable materials to ensure top-tier performance and longevity.

Q: What kind of testing do KTA19 Cummins engines undergo at MEP Power?

A: Each engine undergoes rigorous testing including performance tests, durability tests, and emission tests to ensure it meets all Cummins and industry-specific standards.

Q: How does MEP Power ensure the reliability of the KTA19 Cummins engine?

A: MEP Power implements stringent quality control measures at every stage of the manufacturing process and ensures all parts meet Cummins specifications.

Q: Are there any environmental standards followed during the manufacturing of the KTA19 Cummins engine?

A: Yes, MEP Power complies with all relevant environmental regulations such as EPA and Euro standards to minimize environmental impact during manufacturing.

Q: What is the typical lead time for manufacturing a KTA19 Cummins engine?

A: The typical lead time for manufacturing a KTA19 Cummins engine is between 8 to 12 weeks, depending on the specific requirements and order size.

Q: Does MEP Power provide post-manufacturing support for the KTA19 Cummins engine?

A: Yes, MEP Power offers comprehensive post-manufacturing support including installation assistance, troubleshooting, and maintenance services to ensure optimal engine performance.

Q: How does MEP Power handle customization requests for the KTA19 Cummins engine?

A: MEP Power can accommodate various customization requests. Clients should contact the sales or engineering team to discuss specific requirements and ensure feasibility.

Q: Is there a warranty provided for the KTA19 Cummins engine manufactured by MEP Power?

A: Yes, MEP Power provides a standard manufacturer’s warranty which typically covers defects in materials and workmanship for a specified period.

Q: Can I get a detailed user manual for the KTA19 Cummins engine?