Sure, here are some FAQs along with their answers for manufacturing “KTA50 quality work from MEP Power factory”:

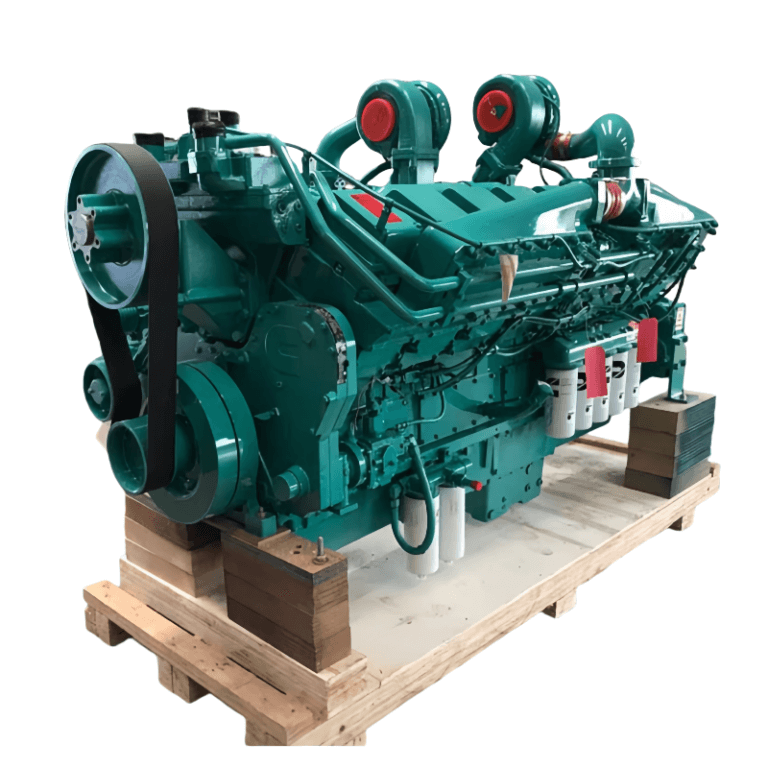

Q: What is the KTA50?

A: The KTA50 is a high-performance diesel engine commonly used in commercial, industrial, and power generation applications due to its reliability and efficiency.

Q: What quality standards does the MEP Power factory adhere to in manufacturing the KTA50?

A: The MEP Power factory follows stringent ISO 9001 and ISO 14001 standards, ensuring that all processes meet high-quality and environmental management criteria.

Q: What materials are used in the KTA50 manufacturing process?

A: The KTA50 is made using high-grade, durable materials like cast iron and steel alloys to ensure longevity and optimal performance under various conditions.

Q: How do you ensure the KTA50 meets regulatory standards?

A: Every KTA50 engine undergoes rigorous testing and certification processes, including emissions testing to comply with EPA regulations and global standards.

Q: What kind of testing is performed on the KTA50 engines?

A: Each KTA50 engine undergoes performance, durability, and reliability testing, including load testing, vibration testing, and high-temperature operation tests.

Q: Can I get custom modifications for the KTA50 from MEP Power factory?

A: Yes, MEP Power factory offers customization options to tailor the KTA50 engine to specific operational needs and applications.

Q: What is the warranty period for a KTA50 engine from MEP Power factory?

A: The KTA50 engine typically comes with a comprehensive 2-year warranty, covering parts and labor for manufacturing defects.

Q: How can I order a KTA50 engine from MEP Power factory?

A: You can place an order by contacting our sales team via email or phone. Detailed information can also be found on our official website.

Q: Are there maintenance services available for the KTA50?

A: Yes, MEP Power factory offers extensive maintenance and support services, including scheduled maintenance, part replacements, and technical support.

Q: What are the lead times for manufacturing and delivery of a KTA50 from MEP Power factory?

A: The standard lead time is approximately 8-10 weeks, depending on order specifications and current production schedules.

These concise responses provide essential information for users interested in the KTA50 engine from MEP Power factory.