FAQs for Sourcing NT855 from MEP Power Factory

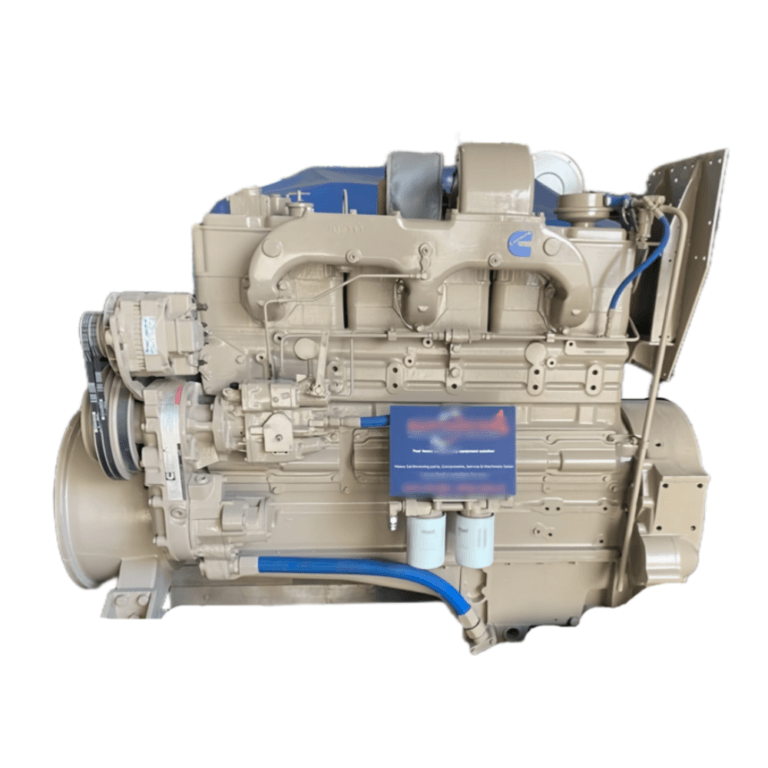

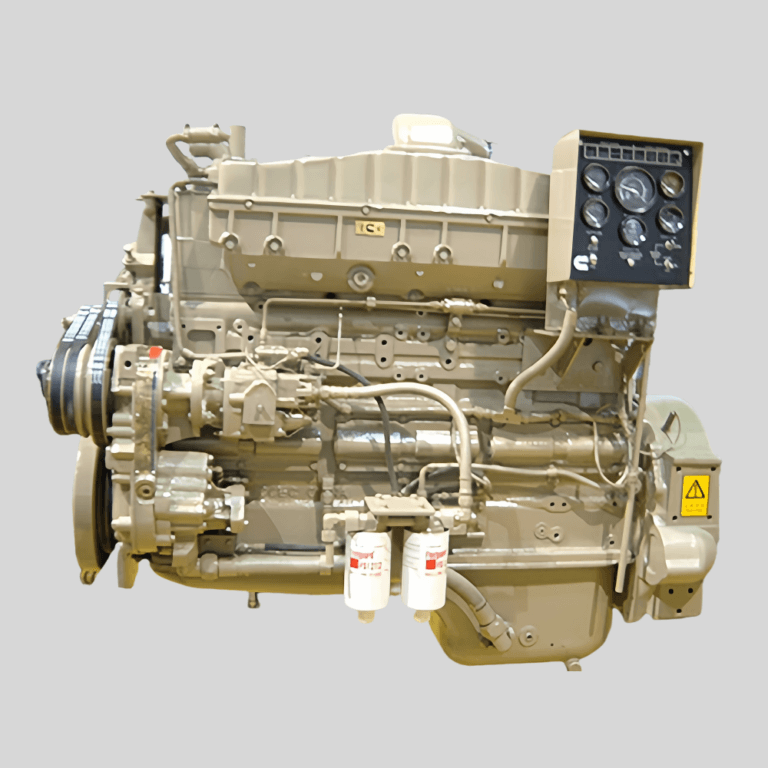

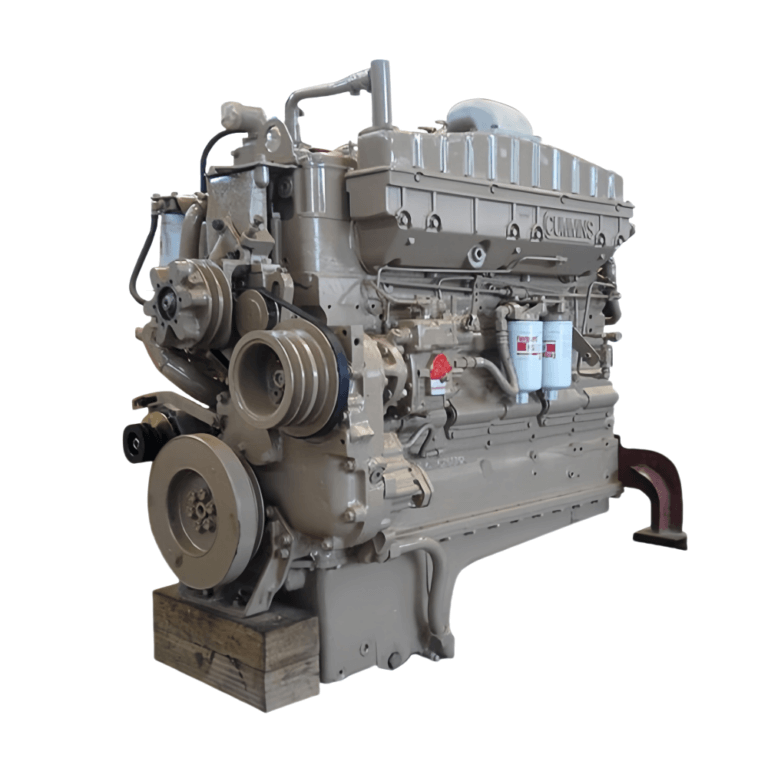

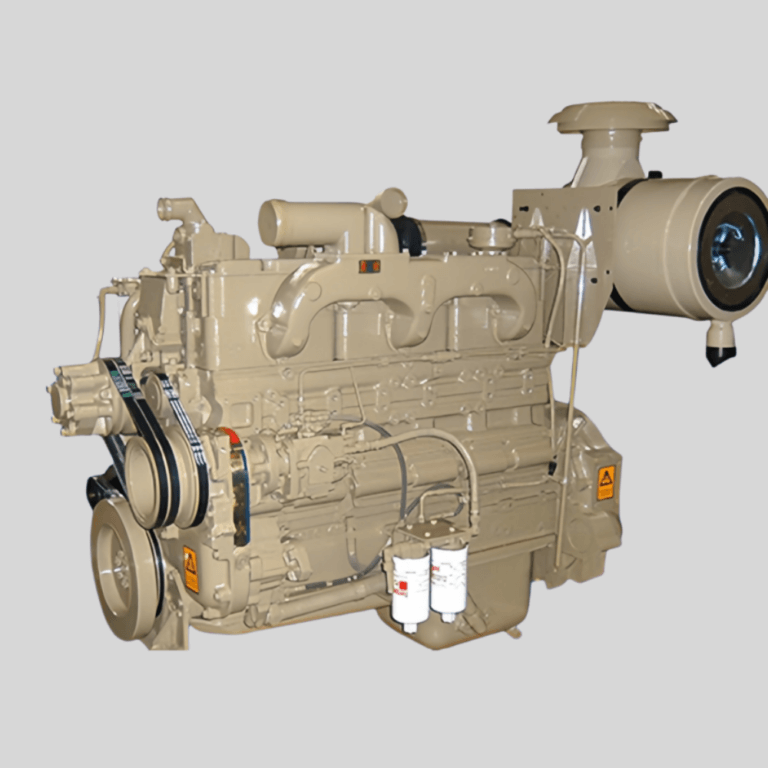

What is the NT855 engine, and what are its key features?

The NT855 is a heavy-duty diesel engine known for its durability, efficiency, and high performance. Key features include a turbocharged design, low fuel consumption, and robust construction suitable for various industrial applications.

Is the NT855 from MEP Power factory genuine?

Yes, MEP Power factory is an authorized manufacturer and supplier of genuine NT855 engines, ensuring you receive a high-quality, reliable product.

What applications is the NT855 suitable for?

The NT855 engine is versatile and can be used in generators, construction machinery, industrial equipment, and marine applications. Its robust design makes it ideal for demanding conditions.

What is the delivery timeline for an NT855 engine?

Delivery timelines can vary based on your location and order quantity. Typically, delivery can range from 2 to 6 weeks. Contact MEP Power factory directly for a precise delivery estimate.

What warranty and support come with the NT855 engine?

MEP Power factory provides a comprehensive warranty and after-sales support for the NT855 engine. Warranty details and support services vary by region, so it’s best to consult with the supplier directly.

Can I get spare parts for the NT855 engine from MEP Power factory?

Yes, MEP Power factory supplies genuine spare parts for NT855 engines, ensuring optimal performance and longevity.

How do I ensure proper installation of the NT855 engine?

It is recommended to have the NT855 engine installed by qualified technicians. MEP Power factory can also provide installation guidance and support to ensure proper setup.

Are there any maintenance requirements for the NT855 engine?

Routine maintenance is essential for the performance and longevity of the NT855 engine. Regular oil changes, filter replacements, and periodic inspections are recommended.

What are the payment terms for purchasing an NT855 engine?

Payment terms generally include options like advance payments, letters of credit, or staggered payments. Discuss your preferred terms with MEP Power factory to find a suitable arrangement.

How do I place an order for the NT855 engine with MEP Power factory?

You can place an order by contacting MEP Power factory directly via their website, email, or phone. Provide the necessary details, and their team will guide you through the ordering process.